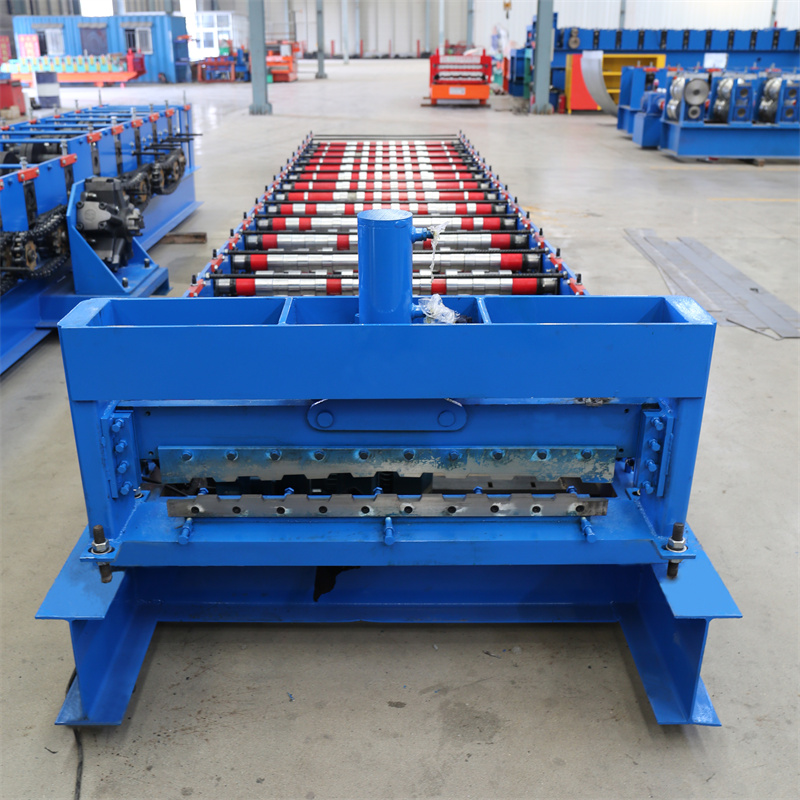

55 77 PU Foam Roller Shutter Door Forming Machine Rolling Shutter Door Making Machine

Machine Pictures

Description

Our company are professional product roll forming machines manufacture, we can make pu roller shutter door roll forming machine,

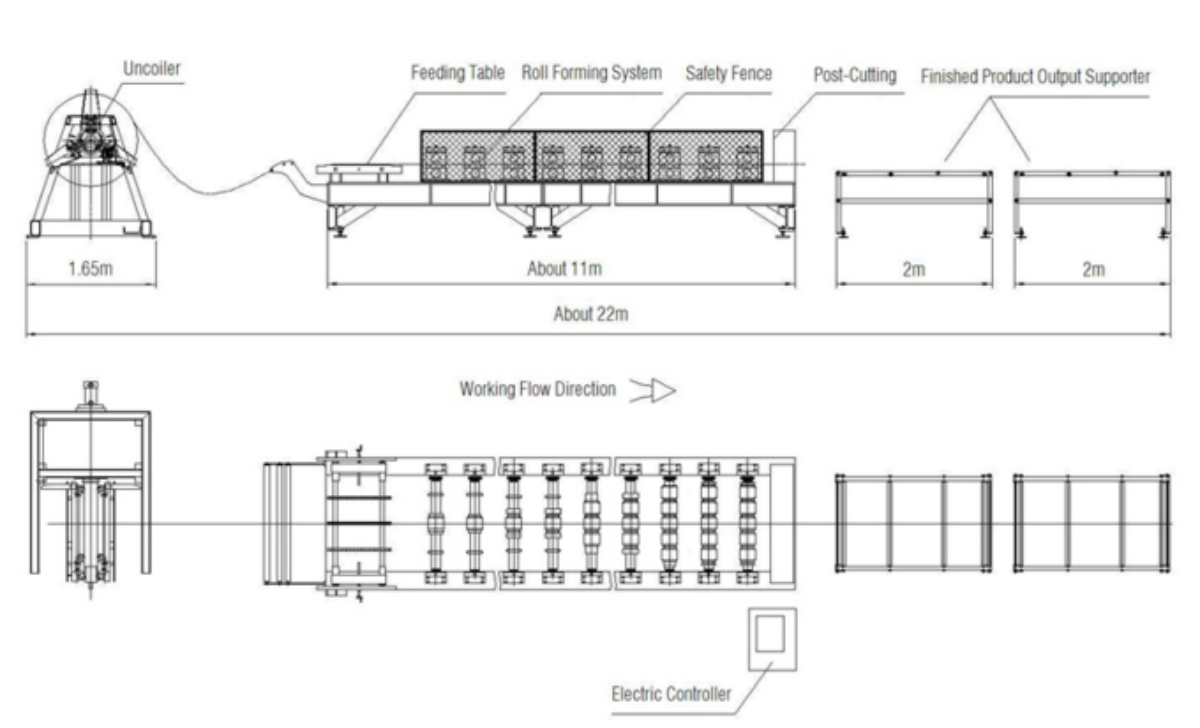

Decoiler ----Roll forming ---- PU injection machine ----straight device----Pneumatic Punching---- Pneumatic cutting platform ---- Run out table

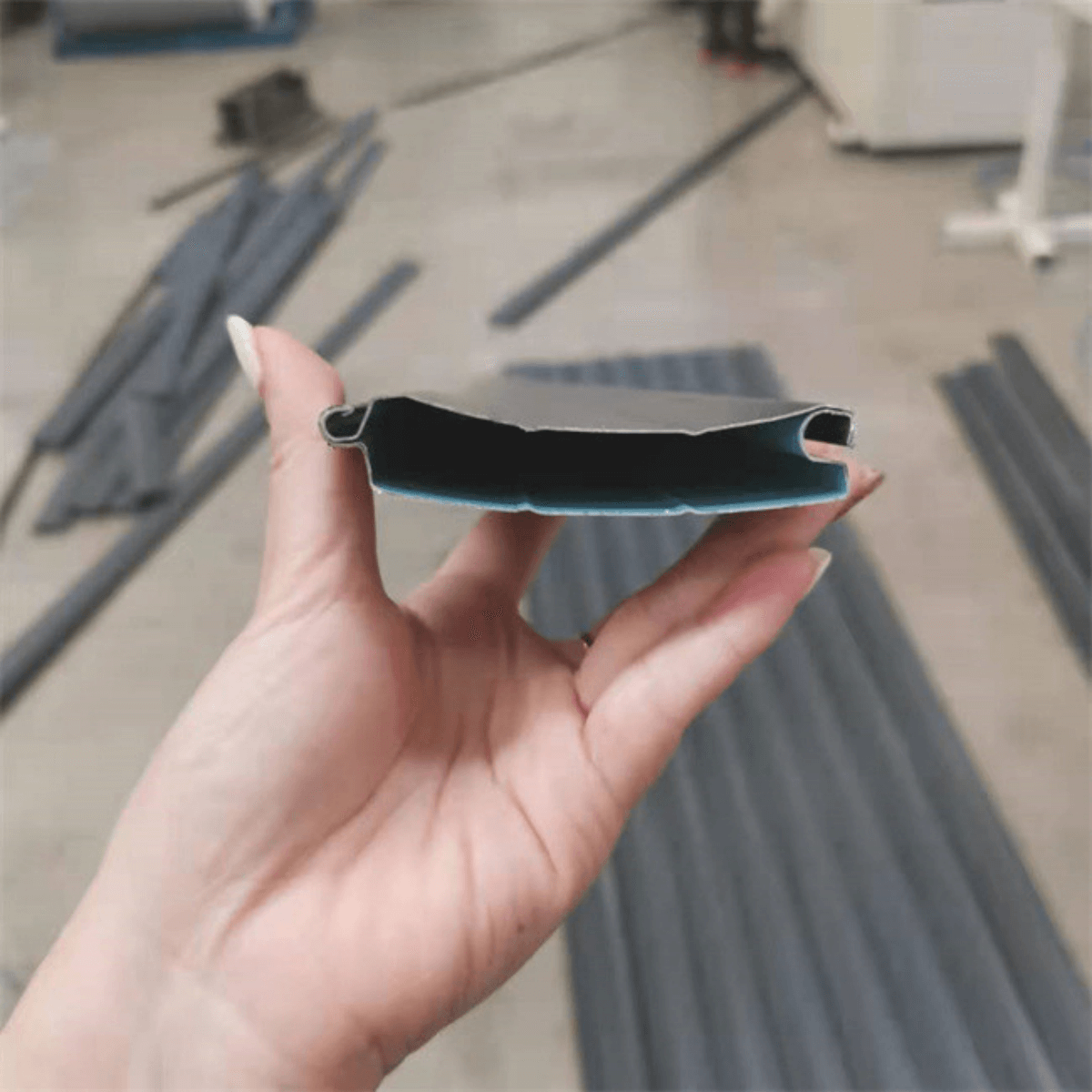

PU rolling shutter slats are produced from Aluminum or Galvanized steel (thickness 0.3-0.5mm or 0.4-0.6mm, and material widths vary according to the required final slats) and PU (Polyurethane) foam insulated continuously; sometimes punching slots are required. The most common PU rolling shutter slat profiles have effective widths 37mm, 42mm, 55mm, 77mm, 98mm and 125mm etc, and we can design and build production lines for some customized rolling shutter slats as well.

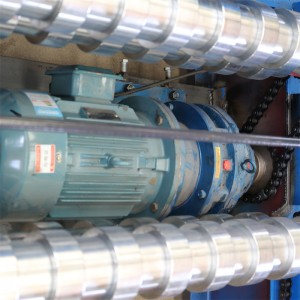

There are two different transmission and roll forming systems optional for a PU rolling shutter slat production line: economical type (chain-brackets transmission and conjoint-stands roll forming system) and upgraded type (gear-box & universal joint shafts transmission and separate-stands roll forming stands).

Technical Details

|

Machine Specifications |

|

| Weight | About 8tons |

| Size | About 32mx1.0mx1.2m(length x width x height) |

| Color | Main color: blue or as your requirement |

| Warning color: yellow | |

|

Suitable Raw Material |

|

| Material | Galvanized Steel Coils |

| Thickness | 0.2 - 0.35mm |

| Yield Strength | 235Mpa |

|

Main Technical Parameters |

|

| Quantity of forming rollers stations | 23 |

| Diameter of forming rollers shafts | 40mm |

| Roll Forming Speed | 15-20m/min |

| Forming rollers material | No.45 steel, coated with chromed treatment |

| Cutter material | CR12 mould steel, with quenched treatment |

| Controlling system | PLC and Converter |

| Electric Power requirement | Main motor power: 7.5kw |

| Hydraulic unit motor power: 4kw | |

| Electric voltage | According to customer’s requirement |

Main Components

|

Decoiler |

1 Set |

|

Guiding Equipment |

1 Set |

|

Roll Forming Unit |

1 Set |

|

Post Cutting Unit |

1 Set |

|

Hydraulic Station |

1 Set |

|

PLC Control System |

1 Set |

|

Reveiving Table |

1 Set |

Production Flows

Uncoiling the sheet---Infeed guiding--Roll forming---Rectifying the straightness---Measure length---Cutting the panel--panels to the supporter (option: automatic stacker)

Advantages

· Germany COPRA software design

· 5 engineers with more than 20 years experience

· 30 professional technician

· 20 sets advanced CNC production lines on site

· Passionate Team

· Installation engineers can reach your factory within 6 days

· 1.5 years maintenance and whole life technical support

Application

This machine is widely used in the production of the door shutters.

Product Photo

FAQ

Q: How to visit our company:

A: 1.Fly to Beijing airport: By high speed train From Beijing Nan to Cangzhou Xi (1 hour),then we can pick up you.

2.Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours),then we can pick up you.

3. Fly to Guangzhou aiport: By air From Guangzhou to Beijing airtpot; By high speed train From Beijing Nan to Cangzhou Xi (1 hour),then we can pick up you.

Q: Does one machine can only produce one style panel profile?

A: Not exactly.For wider and double layer making machine .It can produce more than 2 kinds of panels.

Q: What is your after sales support?

A: We are happy to give advice and we also have skilled technicians available across the world.

Q: What can you do if the machine broken?

A: 1.The machine will be tested before shipment with coil, ensure everything is ready

2.We will prepare some spare parts along with the machine, ensure our customer can solve the issue in a shortest time.Both the sale person and technician can give you the service overseas and make training for the workers,the sale person can make translation, so that the installtion and training will be more clear and easily.

Welcome to inquiry.