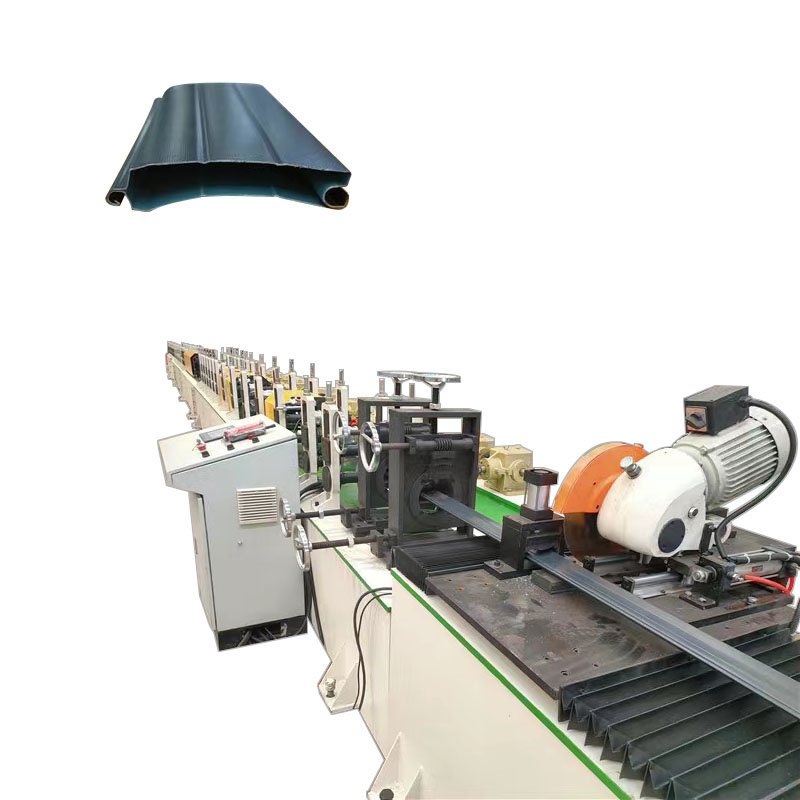

Aluminum New Design Shutter Door Roll Forming Machine High Grade China Manufacture

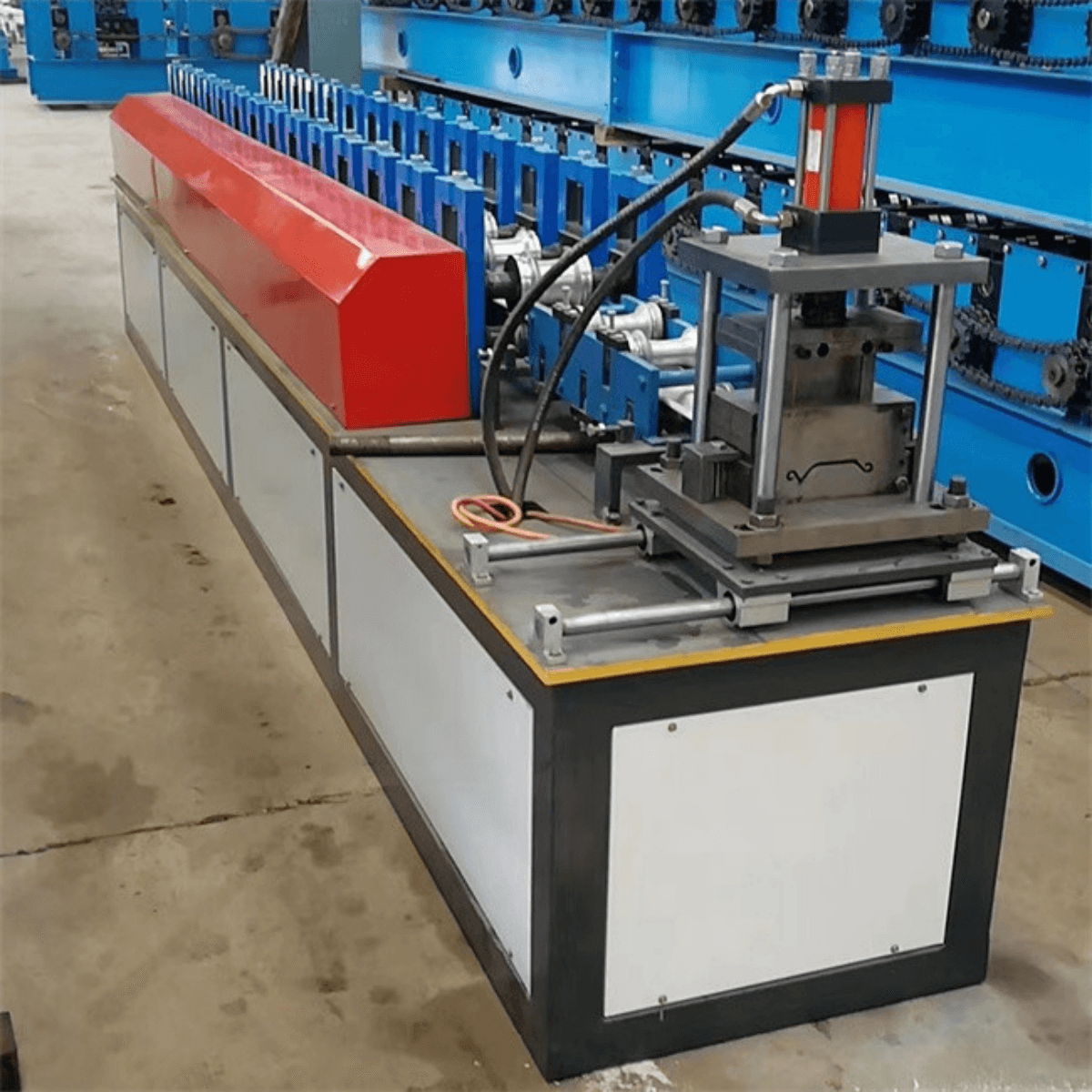

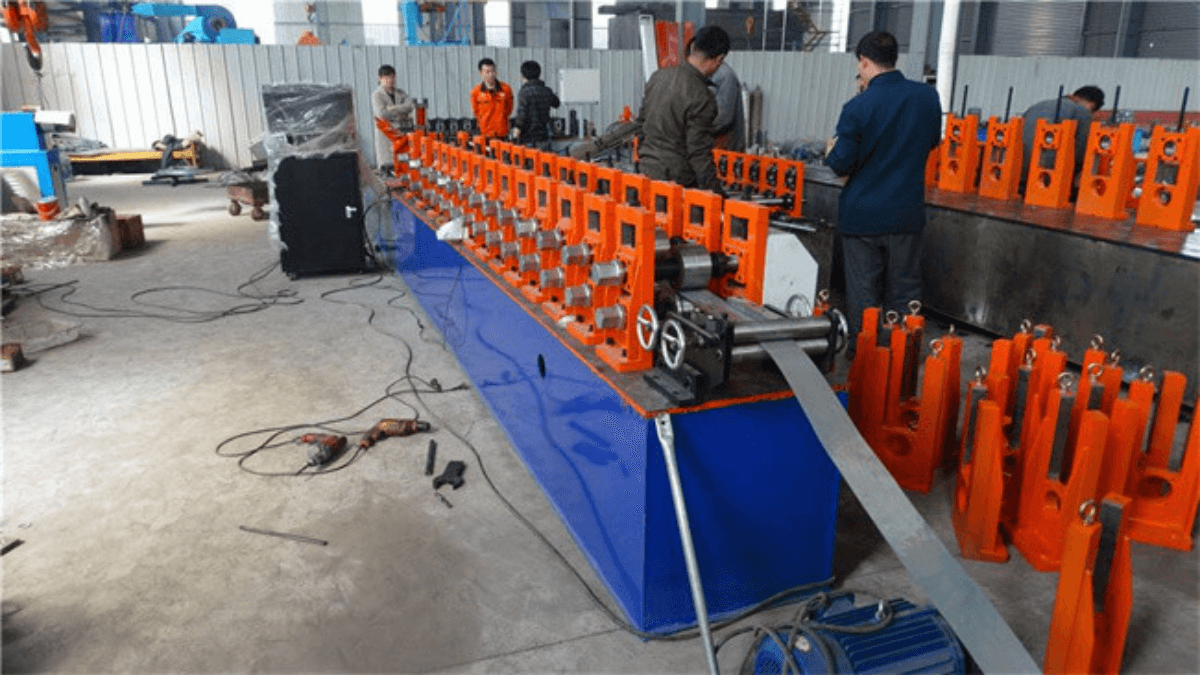

Machine Pictures

Description

Roller shutter door making machine has many parts:

1.Decoiler the coil.

2.Feeder to the punching holes machine(it can make the shutter door slide cover with holes).

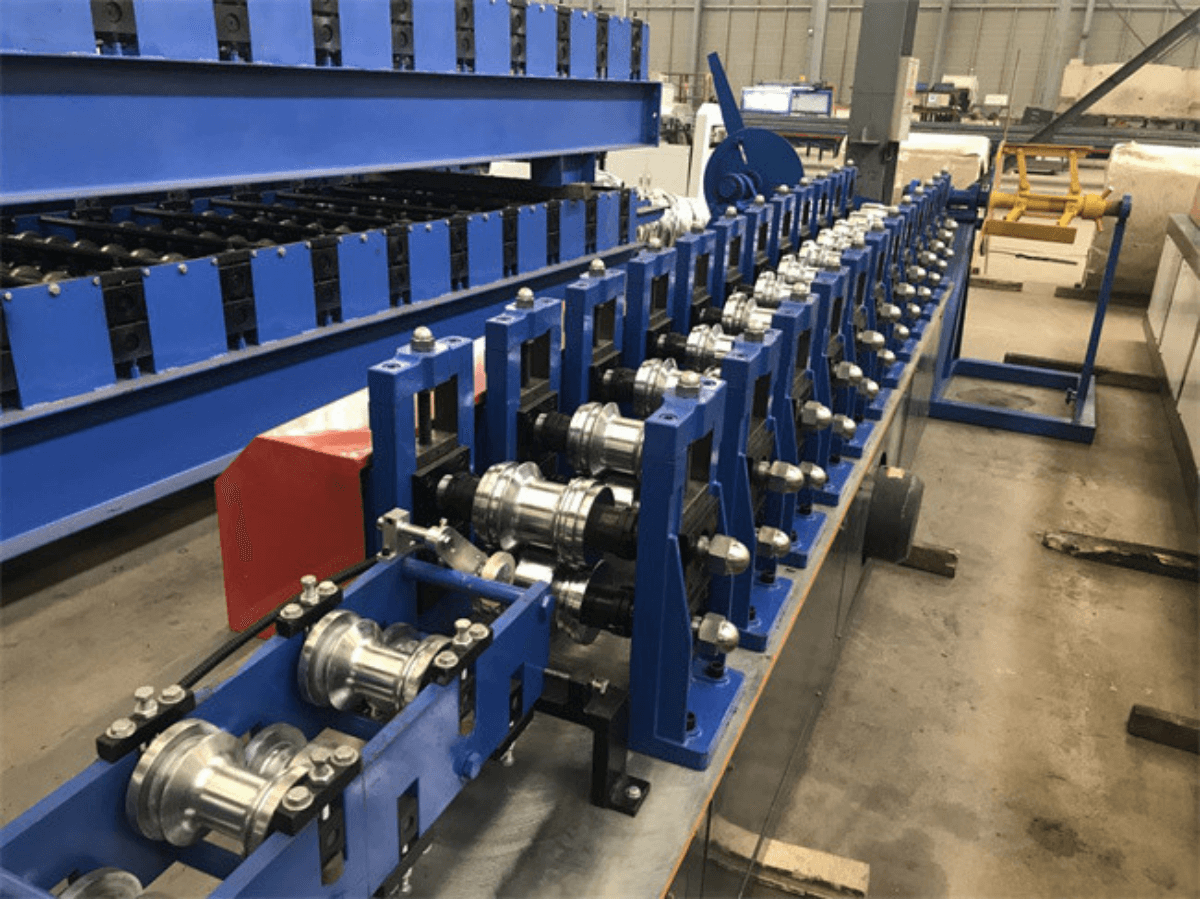

3.Roll forming part, for our mahcine, the forming speed will be 0-30m/min, it is asjustable. Generally we will make the Shutter door roll forming machine with gear drive, it will give machie a strong power to move.

4.Punching the lock holes. This part will together with cutting blade. When it cutting, the machine will punching the holes together.

5.Cutting part. We have two types of cutter for you choose,one is fly saw,another is hydraulic cutter.

Our factory is manufacturing high quality shutter door roll forming machines, and regularly exported to Australia, USA, Thailand, Canada, Indonesia, Philippines, Malaysia, Angola, etc, Colombia, Rwanda, South Africa.

Technical Details

|

Machine Specifications |

|

| Weight | About 3.5tons |

| Size | About 5.6mx1.2mx1.3m(length x width x height) |

| Color | Main color: blue or as your requirement |

| Warning color: yellow | |

|

Suitable Raw Material |

|

| Material | Galvanized Steel Coils |

| Thickness | 0.5-0.8mm or 0.8-1.5mm |

| Yield Strength | 235Mpa |

|

Main Technical Parameters |

|

| Quantity of forming rollers stations | 11-12 |

| Diameter of forming rollers shafts | 60mm |

| Roll Forming Speed | 15-20m/min |

| Forming rollers material | No.45 steel, coated with chromed treatment |

| Cutter material | CR12 mould steel, with quenched treatment |

| Controlling system | PLC and Converter |

| Electric Power requirement | Main motor power: 4kw |

| Hydraulic unit motor power: 3kw | |

| Electric voltage | According to customer’s requirement |

Main Components

|

Decoiler |

1 Set |

|

Guiding Equipment |

1 Set |

|

Roll Forming Unit |

1 Set |

|

Post Cutting Unit |

1 Set |

|

Hydraulic Station |

1 Set |

|

PLC Control System |

1 Set |

|

Reveiving Table |

1 Set |

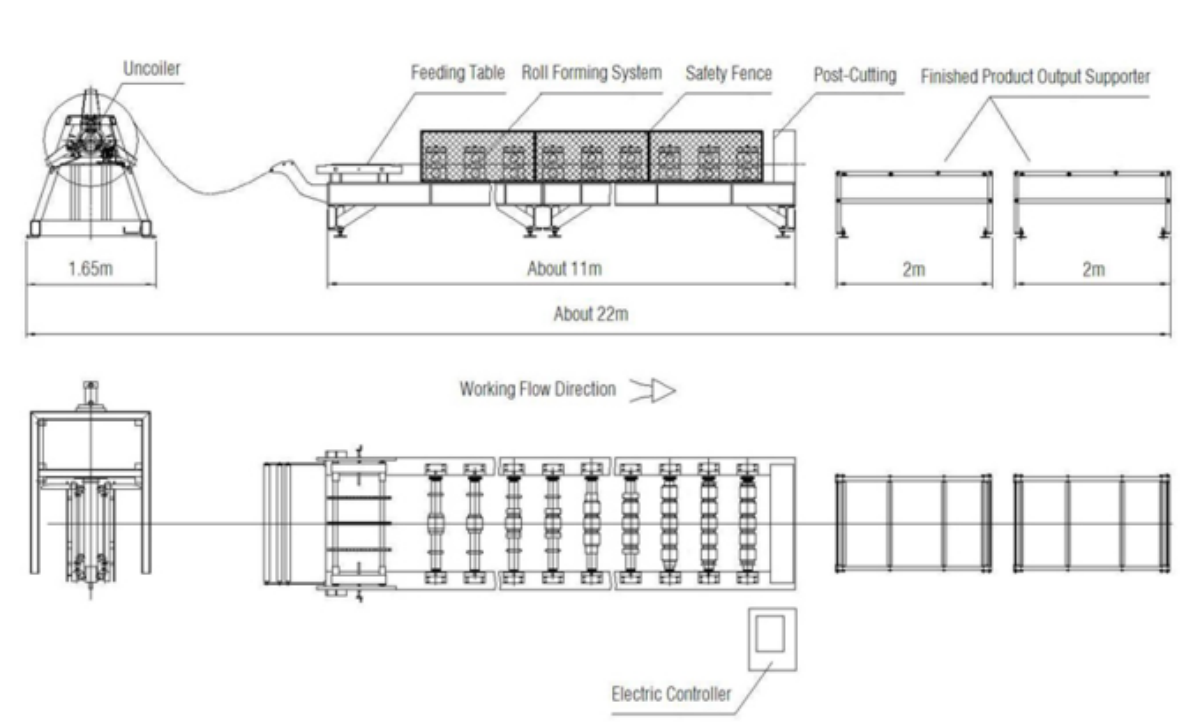

Production Flows

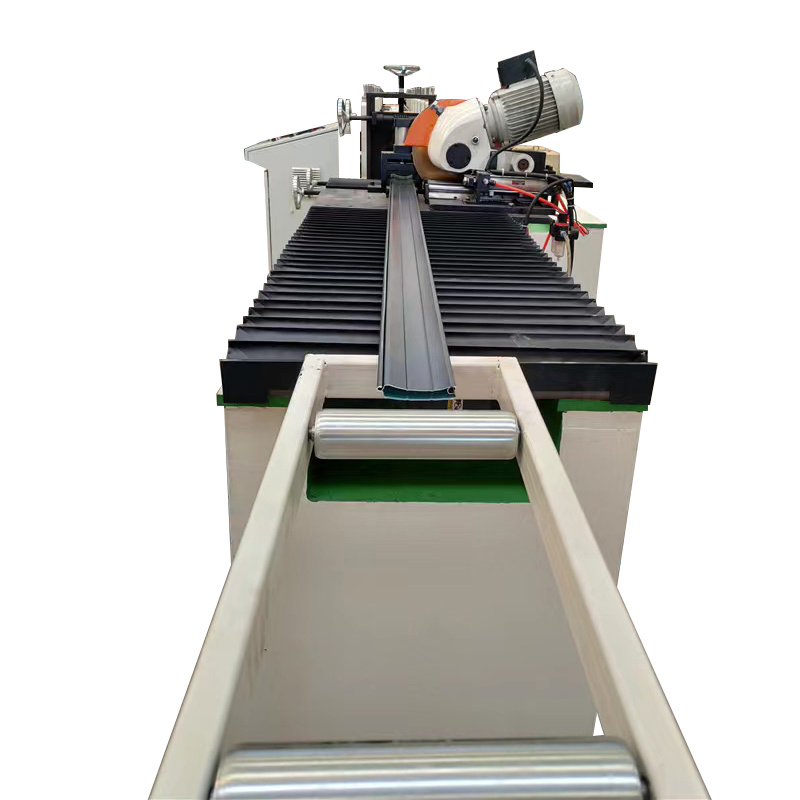

Uncoiling the sheet---Infeed guiding--Roll forming---Rectifying the straightness---Measure length---Cutting the panel--panels to the supporter (option: automatic stacker)

Our Factory Advantages

· Germany COPRA software design

· 5 engineers with more than 20 years experience

· 30 professional technician

· 20 sets advanced CNC production lines on site

· Passionate Team

· Installation engineers can reach your factory within 6 days

· 1.5 years maintenance and whole life technical support

Application

This machine is widely used in the production of the door shutters.

Product Photo