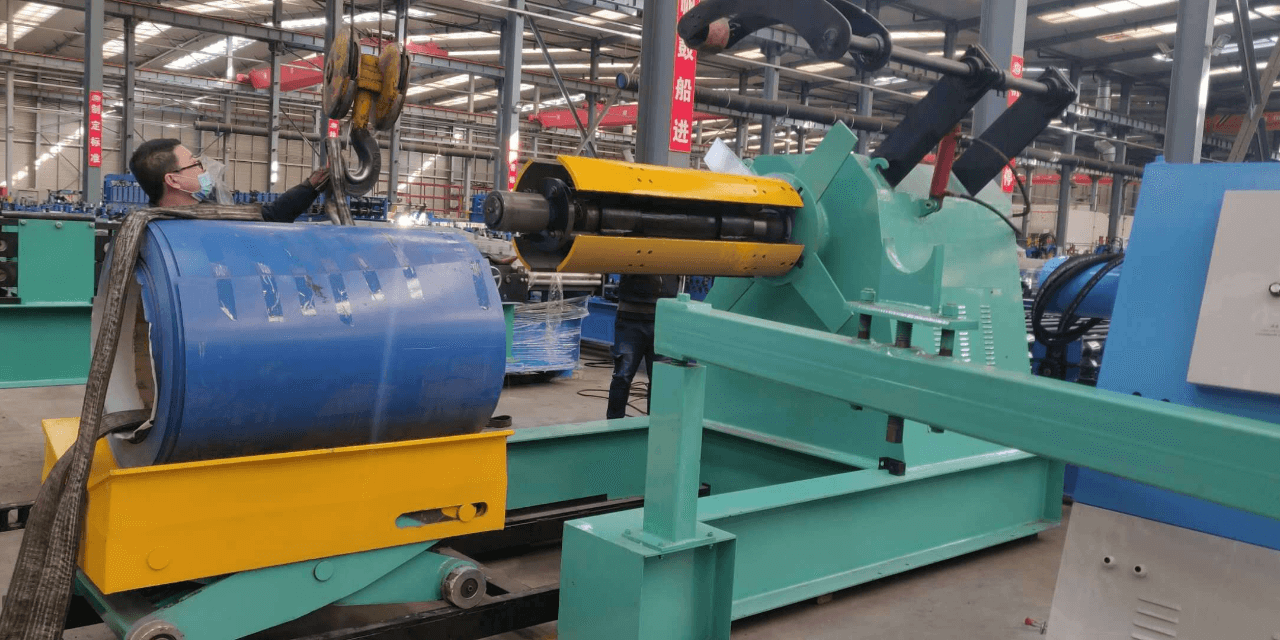

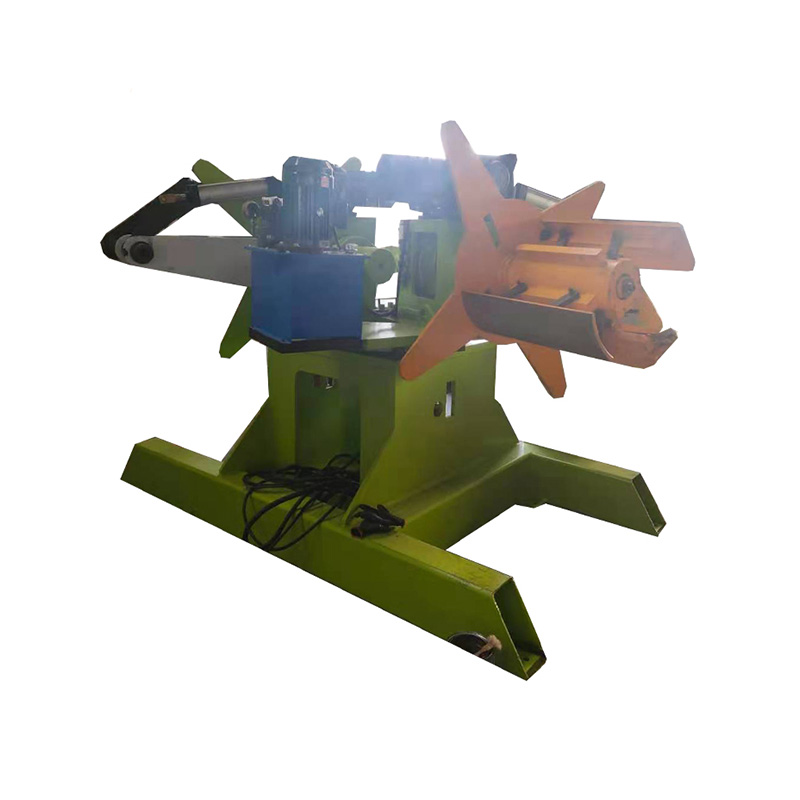

Coil Hydraulic Steel Decoiler 5tons with Loading Car

Machine Pictures

Metal roofing sheet 5 tons hydraulic decoiler with coil car

Metal roofing sheet 10 tons hydraulic decoiler with coil car

Roofing sheet roll forming machine used 5 tons electrical uncoile

Metal roofing sheet 5 tons hydraulic decoiler without coil car

Double-head decoiler

Light guage keel forming machine used 3 tons hydraulic uncoiler

Machine Parameters ( for example the 5 tons hydraulic uncoiler with coil car)

1. Host volume: 2.5 meters long, 1.6 wide, 1.75 meters high

2. Main engine weight: about 2.4 tons

3. Hydraulic pump station: 5 solenoid valve pump station (the pump valve is Beijing Huade brand), power 3kw

4. Host rated power: 4kw (International Trade brand) cycloid reducer

5. Frame body: the base is made of 300H national standard I-beam, and the box body is welded by 16mm thick steel plate

6. Supporting spindle: made of thick-walled seamless steel pipe, shaft diameter 194*45mm

7. Feeding width: 0-1500mm

8. Inner diameter of steel coil: 470-530mm, ±20mm

9. Rated load within 5 tons

10. Hydraulic cylinder: the cylinder diameter of the coiling cylinder is 125mm, one (plus rotation)

11. Electrical control system: adopt Taiwan Delta frequency converter (5.5kw), and domestic Zhengtai electrical control parts,

12. The main machine plus hydraulic or pneumatic pressure arm

Advantages

1. The load-bearing spindle adopts high-strength, fatigue-resistant seamless steel on the back wall, which is processed by turning, with strong strength and heavy load.

2. The roll-up adopts hydraulic control, which is convenient, fast and stable.

3. Electrical control, high precision, good automation, frequency converter control, speed can be adjusted arbitrarily.

Coil Car Parameters

1. Car lifting: double oil cylinder, cylinder diameter 90mm, travel 240mmm

2. Car moves forward: Model 450, hydraulic motor

3. Car discharge: panel length: 1.25 meters, panel width: 1.1 meters

4. Car track: width: 1050mm, length: 2.5 meters

5. Car travel: height travel: 400mm, length stroke: 2.5 meters

6. Car weight 0.9 tons

Packaging & Shipping

Our Services

● Packing method: Bare packing, with waterproof cloth and stow-wood. Imported computer control system packed with waterproof cloth and card board.

● Sales term: 30% deposit by T/T, 70% should be balanced by T/T before delivery.

● Delivery time: 40 working days after receive the advance payment.

● Assemble Cost: Round trip air tickets, room and board, visa cost, commission 100 USD/Day.

● Warranty: 18 Months, once the spare parts breakdown, please send us the old parts, we will send new parts to you for free.

Company Information

We have been established in 1995 as a professional manufacturer of ROLL FORMING MALCHINE. We use AUTO CAD design software. With more than 10 years of experience and strict quality control, our products meet International Standard and enjoy great popularity all over the world. Now We are the leading manufacturer of roll forming machine in China.

We manufacture various kinds of roll forming machines for producing such products as Roof Tile, Wall Panel, Roofing Corrugated Sheet, Floor Deck, C & Z Purling, Highway Guardrail, Sandwich Panel, Container Board, Car Panel, Roll Shutter Door, Downspout, Decorated gusset, Steel Pipe, etc.

FAQ

1. How many times to delivery?

Generally the delivery time is 35 working days.

2. How can you guarantee your machine quality?

I am Elna,sales manager of Botou Golden Integrity Roll Forming Machine Co.,LTD. We are more than 15 years to do and export roll forming machines. And, we have strong engineer team to design your machines' drawings and provide you with comfortable and timely after-sale services. Additionally, we have mature workers to do your roll forming machines. So, buy roll forming machines from our comppany will save money and time.

3. If i don't have profile drawing, how can i buy the machine?

Dear, it's okay. Please provide me with your profile drawing. And answer me some below questions and our engineer will draw for your needed profile drawings.

Question 1: What is your raw material? (GI/PPGI or other special materials?)

Question 2: what is your raw material's thickness? (0.3-0.7mm is a normal range)

question 3:What is your input(feeding)width?

Dear, Please provide me with your Whatsapp number and i can send you our catalog and more details.