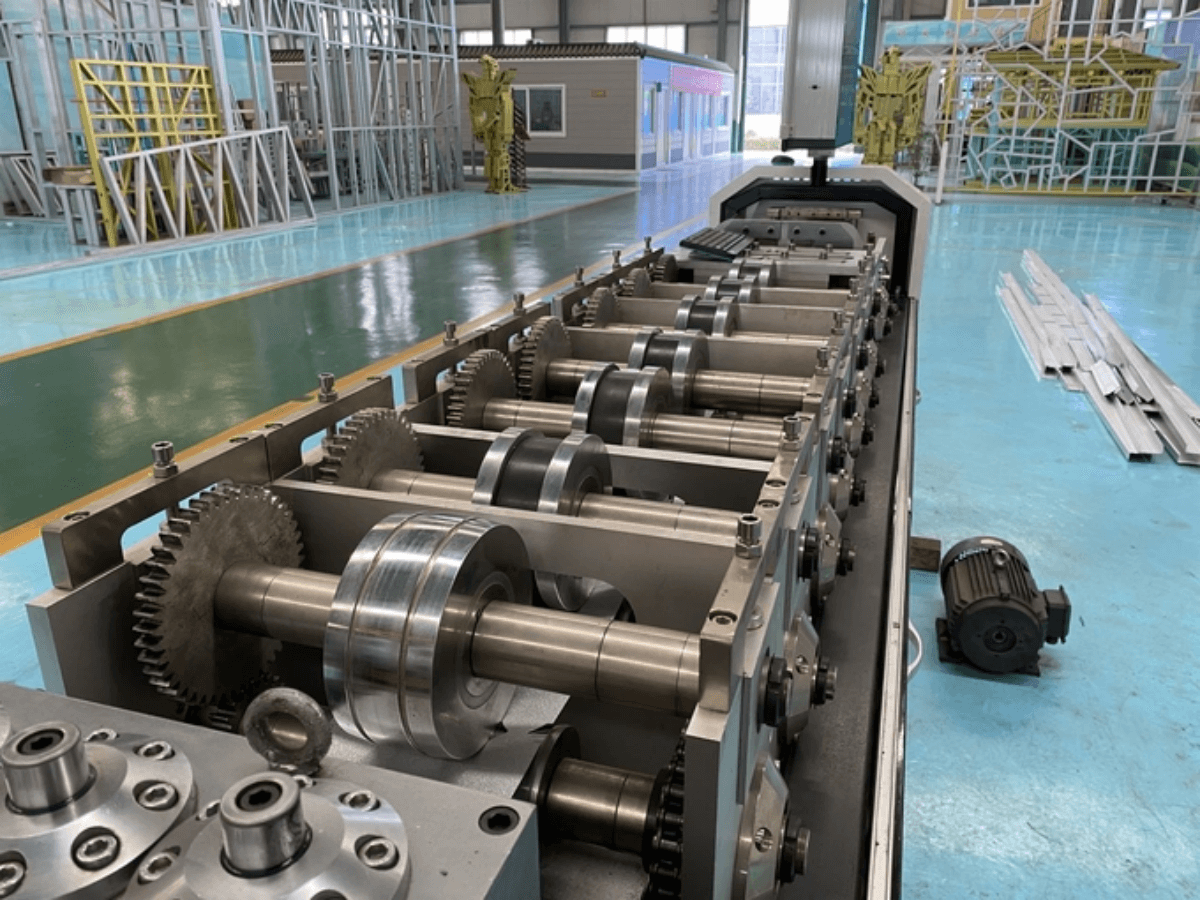

0.7 – 1.2mm Thickness Automatic C89 LGS Framing Machine 3000m Per Hour Max Speed

Machine Pictures

Production Flows

Decoiling --- Levelling-----Punching ---- Roll Forming ----- Ink Code ----- Cutting ---- Profile

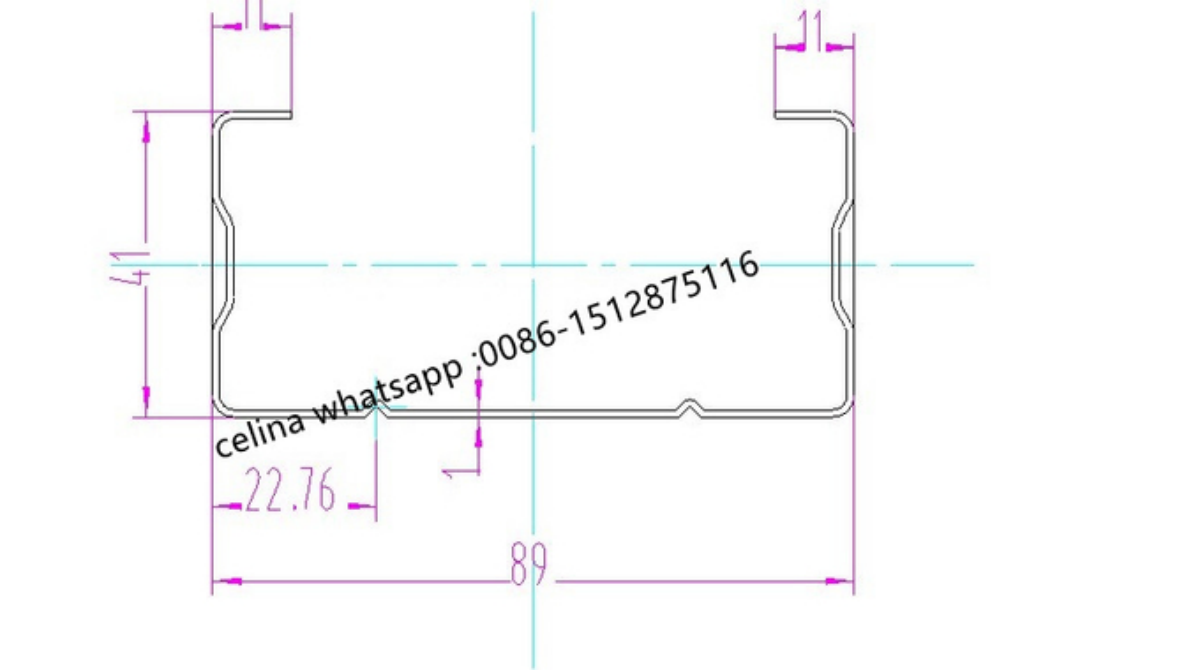

Profile Drawing

Technical Details

|

Light Gauge Steel Framing Machine |

|

| Feeding material | G300-G550 zinc plated, aluminum-zinc plated coil |

| Thickness | 0.75 |

| m/h | |

| Normal production speed | 300-700m/h |

| Main unit power | 7.5Kw |

| Voltage | 380V/50Hz/3phase |

| Hydraulic power | 5.5Kw |

| Inkjet printer | Standard |

| Size | 4.9m*1.0m*1.5m |

| Weight | Approx 4500kg |

Main Components

|

No. |

Description |

|

1 |

Dead loads are determined according to architectural details |

|

2 |

Earthquake loads are calculated according to related specifications for proper zone |

|

3 |

Critical roof purlin, ceiling beam, wall stud and floor joist are checked against imposed loads in order to prevent member forces to exceed the capacity |

|

4 |

Floor joists are analyzed and designed by Vertex BD software |

|

5 |

Include CAD and CAM software |

Application

The light steel villa keel/house framing machine can meet the manufacturing needs of All frame keels of low-rise single-family or conjoined building frames (including walls, floor Beams and roof trusses) with one click.

The frame keel system manufactured by it can be Compatible with the existing brick-concrete structure, wood structure and heavy steel structure.

Intelligent keel equipment cannot only be produced in the factory, but also can be Placed in a container and transported to a remote construction site for on-site production.

Light gauge steel products are known to offer a range of construction related benefits most notably; speed of construction, cost-effectiveness, and safety.

They are also popular due to the products’ unique lightweight characteristic which makes them easy and safe to handle both during fabrication and construction.

Product Photo

Advantages

· Germany COPRA software design

· 5 engineers with more than 20 years experience

· 30 professional technician

· 20 sets advanced CNC production lines on site

· Passionate Team

· Installation engineers can reach your factory within 6 days

· 1.5 years maintenance and whole life technical support

FAQ

1. Does one machine can only produce one style panel profile?

Not exactly.For some making machine. It can produce more kinds of panels by change their rollers.

2. Do you have after sales support?

Yes, we are happy to give advice and we also have skilled technicians available across the world.We need your machines running in order to keep your business running.

3. How to visit your company?

a.Fly to Beijing airport: By high speed train From Beijing Nan to Cangzhou Xi (1 hour), then we can

pick up you.

b.Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours),

then we can pick up you.

4. What can you do if the machine broken?

Our machine's warranty period is 12 months,if the broken parts can't repair,we can send the new parts replace the broken parts freely,but you need pay the express cost yourself.if after warranty period,we can through negotiation for to solve the problems,and we supply the technical support for the whole life of the

equipment.

5. Can you be responsible for transport?

Yes,please tell me the destination port or address.we have rich experience in transport.

6. Why your price is higher than others?

As we persist on that each factory should put quality at the first place. We spend time and money

on developing how to make machines much more automatic, accurate and high quality.

We can make sure that our machine could use more than 10 years without any problem. We can provide 18 months free quality

assurance.

Normally speaking, welded pipe making machine could be made without 45 working days.

If you need machines in a hurry, we can make it for you less than a months.

Welcome to contact with us!