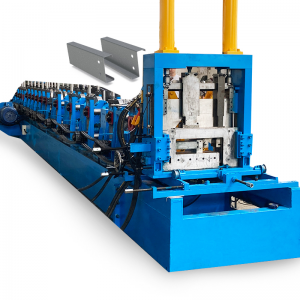

CZ Purlin Roll Forming Machine Automatic C Purlin Forming Machine Z Steel Frame Making Machine

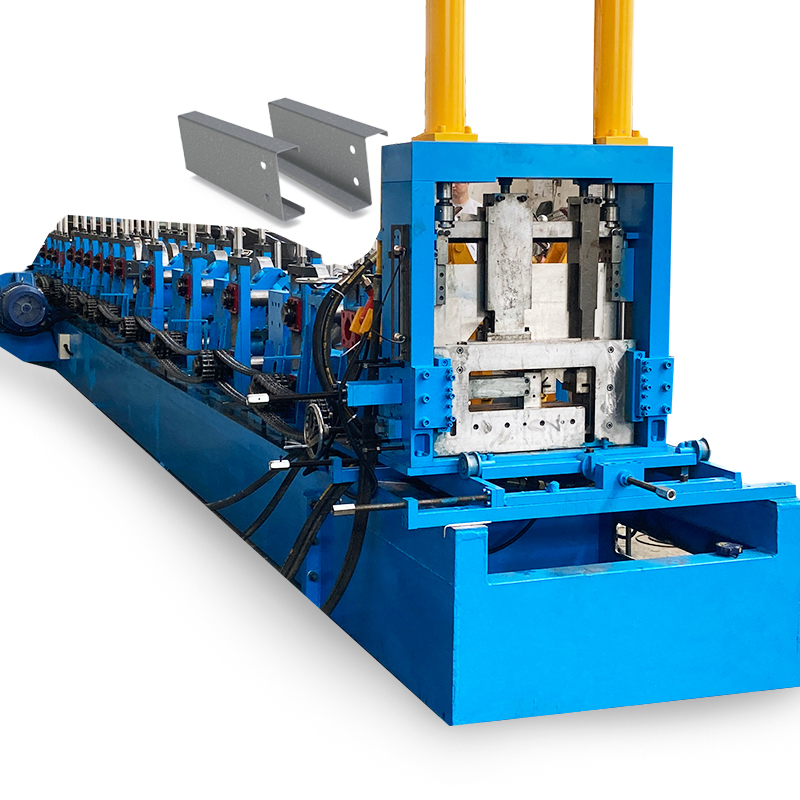

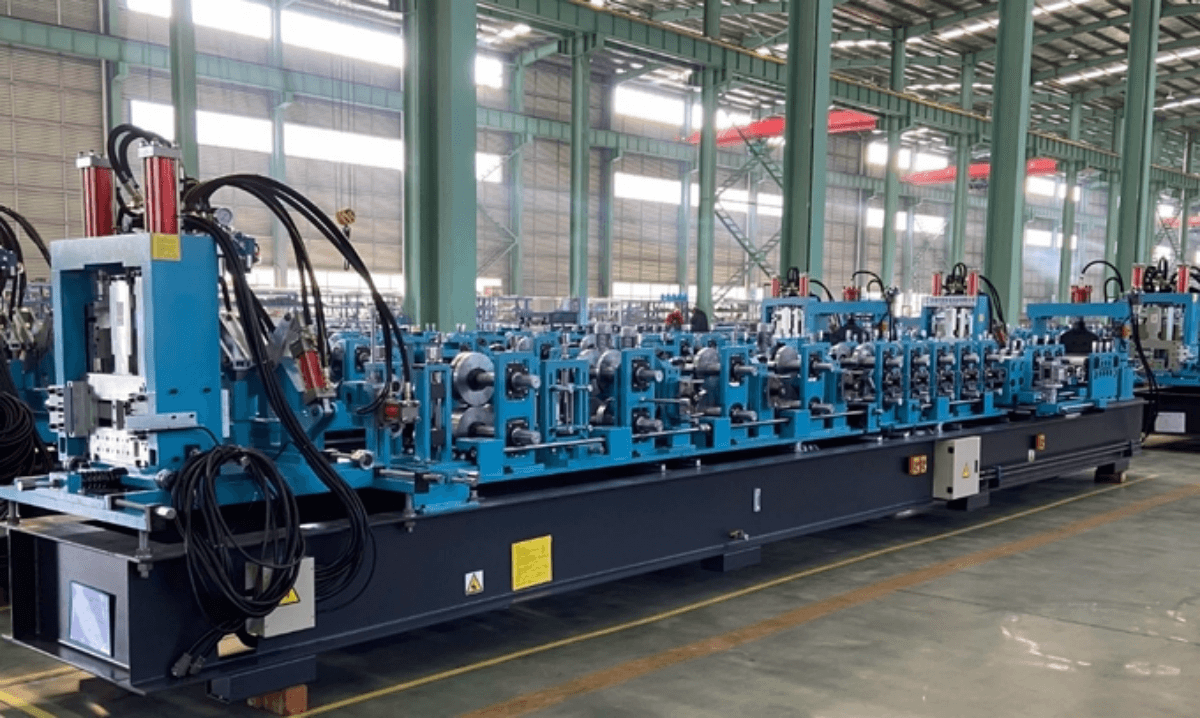

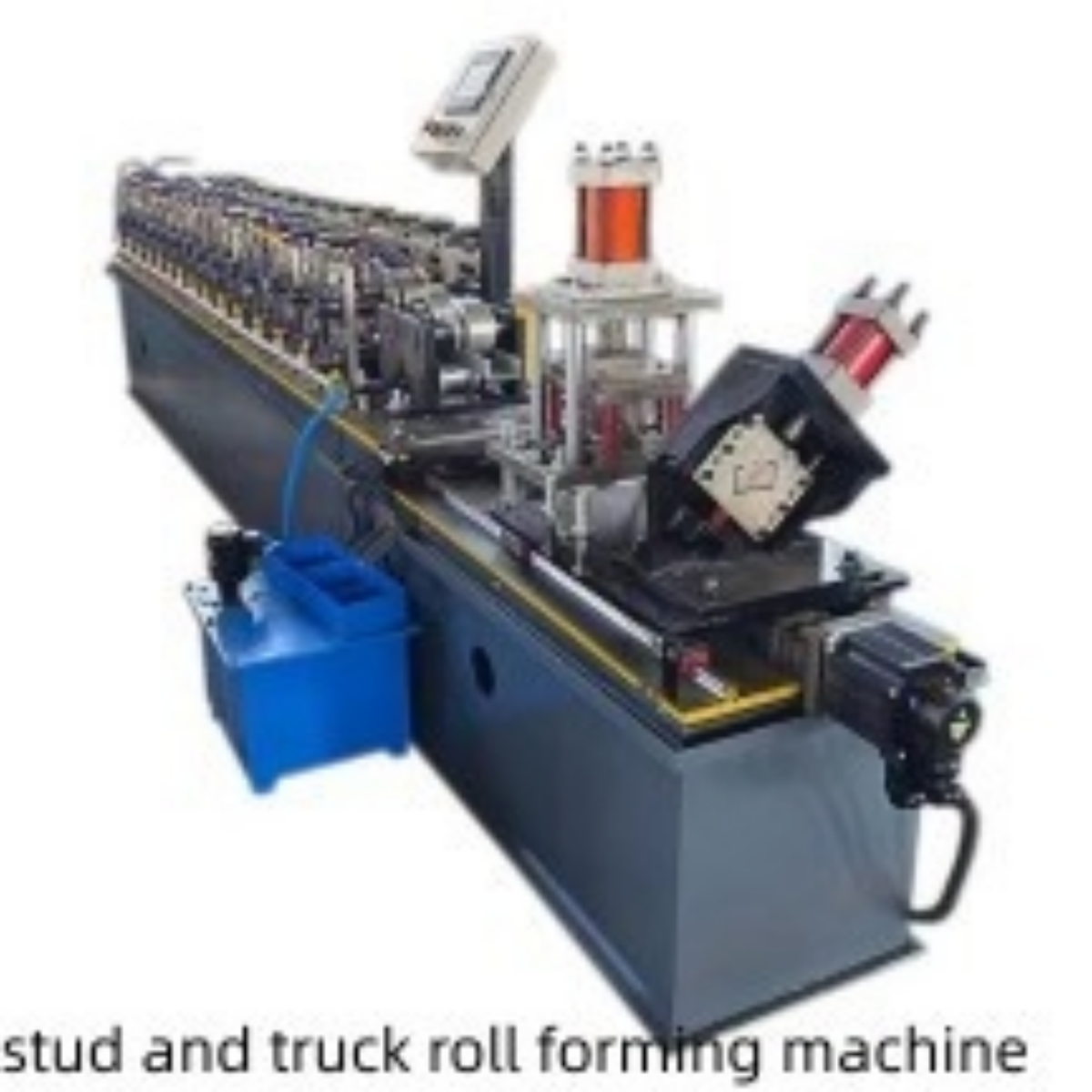

Machine Pictures

Description of CZ purlin roll forming machine

CZ purlin roll forming machine automatic size-change type are as follows:

1. Produce different purlin size without changing rollers or spacers,it can produce the size is: 80-300mm width, 40mm-80mm height.

2. Don't need changing cutter for different size,is very easy.

3. Easy operation, low maintenance cost

4. Have PLC and button to change the raw material size,if you need other size, please contact me.

5. Optional Punch hole at any position of purlin web side and flange side,is easy to operate.

6. The machine also named by different countries:Purlin roll forming machine, c z purlin roll forming machine, z purlin roll forming machine, c-purlin roll forming machine, z-purlin roll forming machine, c steel frame making machine, Z steel framing roll forming machine, c purlin automatic machine, c purlin machine manufacture, z purlin machine manufacture, cz purlin machine, c purlin steel making machine, purlin machine price, cz purlin roll forming machine China, purlin roll forming machine, steel purlin manufacture, c purlin making machine automatic, c purlin making machine and z, metal building c purlin, galvanized c purlins machine, galvanized metal purlin making machine, steel purlin manufactures, c channel purlin machine, steel structural cz purlin making machine, c section roll forming machine, z section making machine, purlin frames cold roll forming machine, full automatic c&z purling machine China manufacture.

Our factory is manufacturing high quality CZ purlin roll forming machines, and regularly exported to Australia, USA, Thailand, Canada,Turkey, Indonesia, Philippines, Malaysia, India, Angola, etc.

Technical Details

|

Machine Specifications |

|

| Weight | About 10 tons |

| Size | About 13mx1.3mx1.3m(length x width x height) |

| Color | Main color: blue or as your requirement |

| Warning color: yellow | |

|

Suitable Raw Material |

|

| Material | Galvanized Steel Coils |

| Thickness | 0.5-0.8mm or 1.5-3mm |

| Yield Strength | 235Mpa |

|

Main Technical Parameters |

|

| Quantity of forming rollers stations | 18 |

| Diameter of forming rollers shafts | 60mm |

| Roll Forming Speed | 20-30m/min |

| Forming rollers material | No.45 steel, coated with chromed treatment |

| Cutter material | CR12 mould steel, with quenched treatment |

| Controlling system | PLC and Converter |

| Electric Power requirement | Main motor power: 22kw |

| Hydraulic unit motor power: 5.5kw | |

| Electric voltage | According to customer’s requirement |

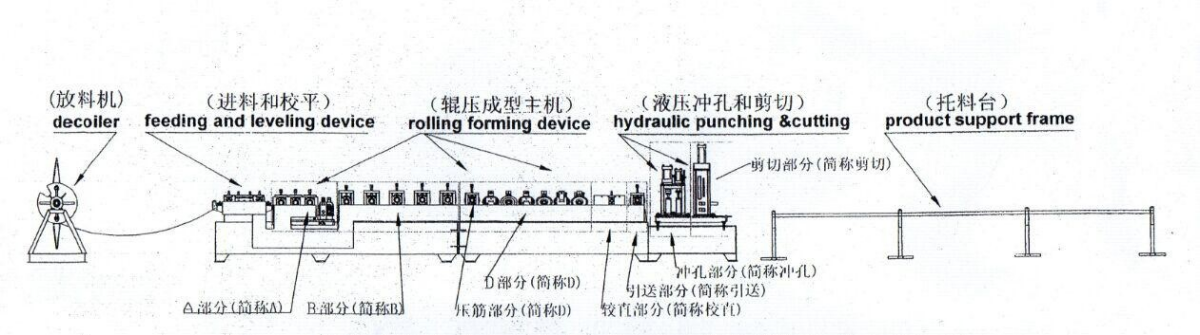

Main Components

|

Decoiler |

1 Set |

|

Guiding Equipment |

1 Set |

|

Roll Forming Unit |

1 Set |

|

Post Cutting Unit |

1 Set |

|

Hydraulic Station |

1 Set |

|

PLC Control System |

1 Set |

|

Reveiving Table |

1 Set |

|

Punching device |

2 Set or according to your request |

Production Flows

Uncoiling the sheet---Infeed guiding--Roll forming---Rectifying the straightness---Measure length---Cutting the panel--panels to the supporter (option: automatic stacker)

Advantages

We have rich experience of production and exported, we cooperate closely with many famous companies to absorb and update the latest technology and use it on our machine to meet the international market requirement.

Our customized design, we design different C Z purlin machine to meet different customized request.

We will test and inspect the machine before shioment,and provide whole life technical support service. We will dspatch our technician to install and train your worker to operate the machine.

Application

This machine is widely used in the production of the horizontal or wall for structural support in buildings, steel buidling.

Product Photo

Recommended Products

FAQ

Q: Do you provide installing and training overseas?

A: Overseas machine install and worker training services are optional

Q. What will you do if the machine is broken?

A4: We provide 18 months free warranty and free technical support for the whole life of any machine. If the broken parts can't repair, we can send the new parts replace the broken parts freely, but you need pay the express cost by yourself. If it is beyond the warranty period, we can negotiate to solve the problem, and we supply the technical support for the whole life of the equipment.

Q: How is your after sales support?

A: We provide technical support on line as well as overseas services by skillful technicians.

Q. What's your payment terms and delivery time?

A: 30% as the deposit by T/T in advance, 70% as the balance payment by T/T after your inspect the machine well and before delivery. Of course your payment terms are acceptable. After we get down payment, we will arrange production. About 30-45 days for delivery.