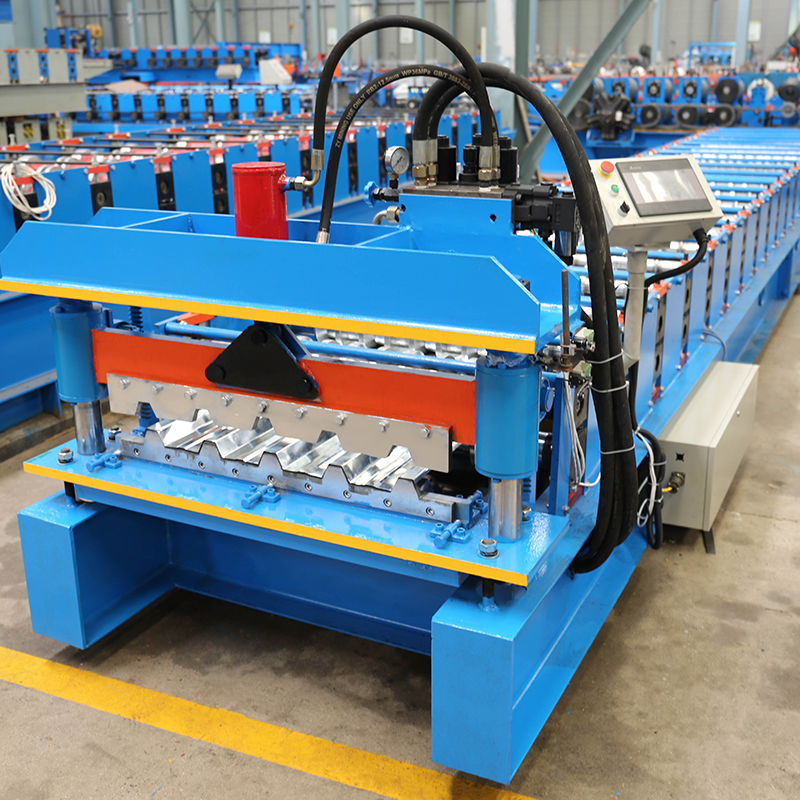

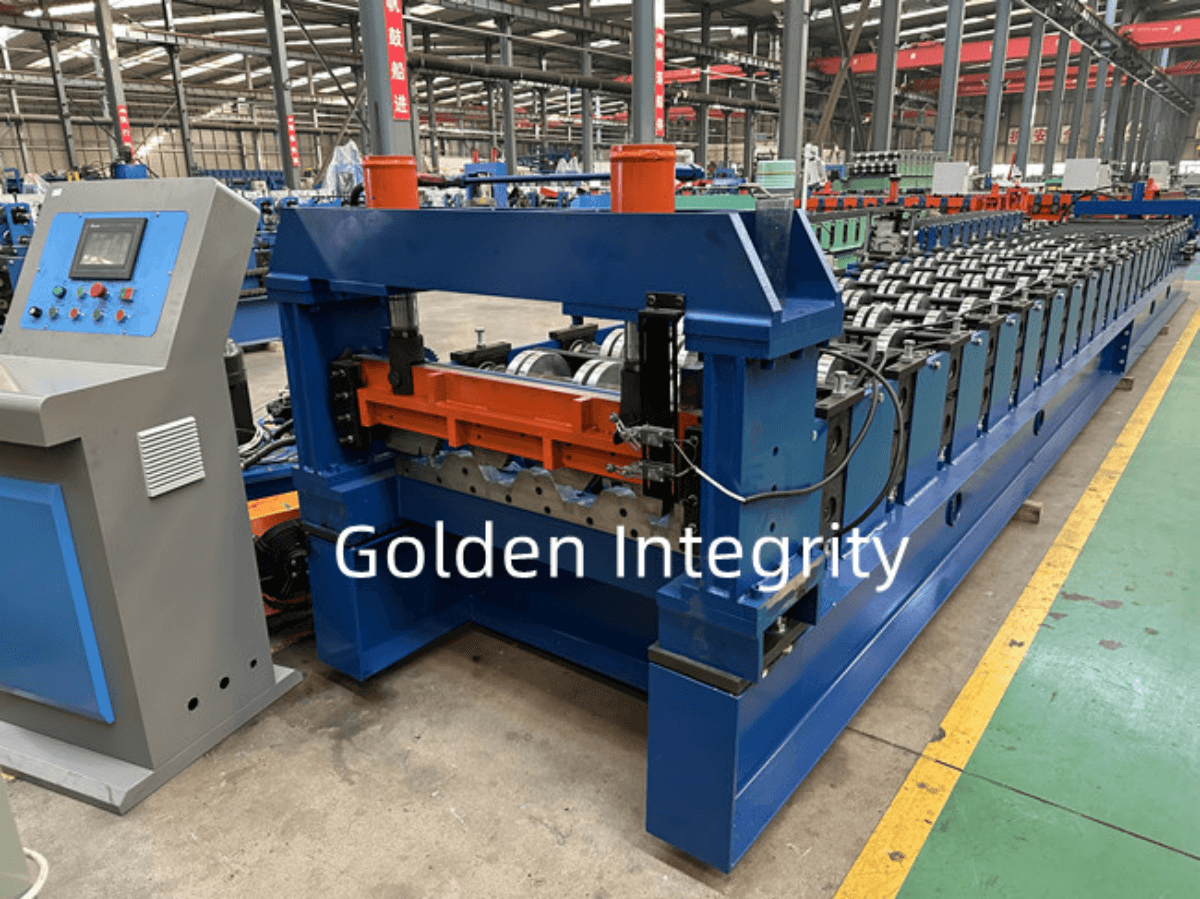

Floor Tile Making Machine Galvanized Steel Floor Decking Sheet Roll Forming Machine

Machine Pictures

Description

Metal roofing decks are available in a variety of types including narrow rib, intermediate rib, wide rib, and deep rib, and are used to support insulation or lightweight concrete and the waterproof membrane of a roof.

These metal roofing deck can be left exposed for open ceiling designs or manufactured with added acoustical perforations

Our automatic deck panel machine consist of decoiler, control by PLC and encoder which cut automatically at required length. Easy to operate.

We have various designs, coil width from 900-1250mm all have.

Technical Details

|

Machine Specifications |

|

| Weight | About 9000kgs |

| Size | About 10mx2.2mx1.3m(length x width x height) |

| Color | Main color: blue and orange |

| Warning color: yellow | |

|

Suitable Raw Material |

|

| Material | Galvanized Steel Coils |

| Thickness | 0.8-1.5mm |

| Yield Strength | 235Mpa |

|

Main Technical Parameters |

|

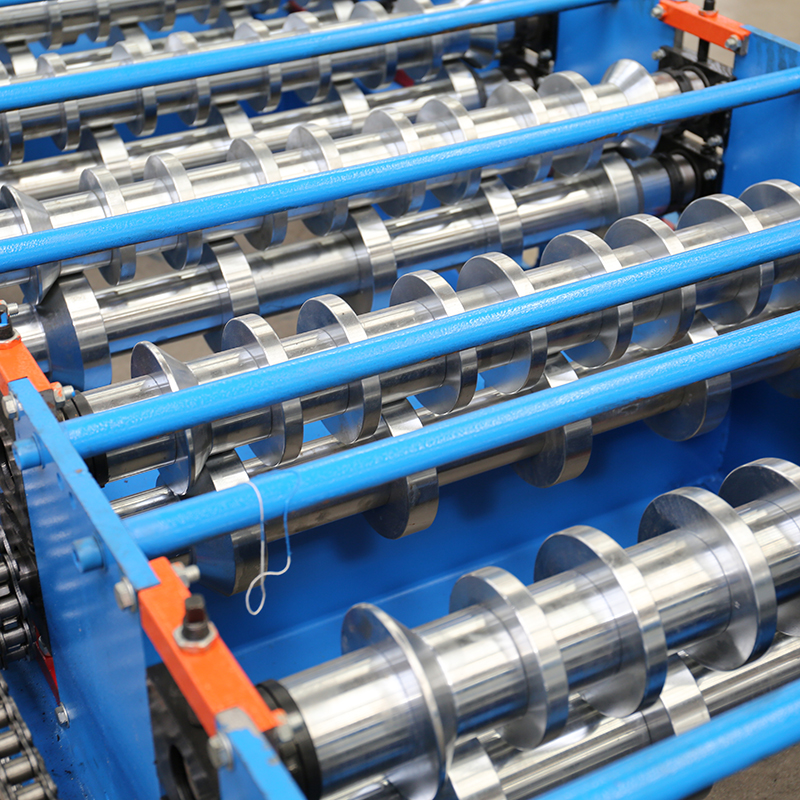

| Quantity of forming rollers stations | 22-25 |

| Diameter of forming rollers shafts8 | 90mm solidt |

| Roll Forming Speed | 12-15m/min |

| Forming rollers material | No.45 steel, coated with chromed treatment |

| Cutter material | CR12 mould steel, with quenched treatment |

| Controlling system | PLC and Converter |

| Electric Power requirement | Main motor power: 2*11kw |

| Hydraulic unit motor power: 5.5kw | |

| Electric voltage | According to customer’s requirement |

Main Components

|

Decoiler |

1 Set |

|

Guiding Equipment |

1 Set |

|

Roll Forming Unit |

1 Set |

|

Post Cutting Unit |

1 Set |

|

Hydraulic Station |

1 Set |

|

PLC Control System |

1 Set |

|

Reveiving Table |

1 Set |

|

Hydraulic pre cutting system |

Optional |

Production Flows

Uncoiling the sheet---Infeed guiding--Roll forming---Rectifying the straightness---Measure length---Cutting the panel--panels to the supporter (option: automatic stacker)

Advantages

Passionate Team

· Installation engineers can reach your factory within 6 days

· 2 years maintenance and whole life technical support

· 5 engineers with more than 20 years experience

· 30 professional technician

· 22 sets advanced CNC production lines on site

FAQ

1) Q: Do you have after sales support?

A: Yes, we are happy to give advice and we also have skilled technicians available across the world. We need your machines running in order to keep your business running.

2) Q: How do your machines compare with other big companies in this market?

A: We are up to date with the latest technology and improve our machines accordingly.

3) Q: How does your factory do regarding quality control?

A: Quality is priority. MACTEC People always attach great importance to quality control from the very beginning to the end of the production. Every product will be fully assembled and carefully tested before it's packed for shipment.

4) Q: Do you sell only standard machines?

A: No, most of our machines are built according to customers specifications, using top brand name components.

5) Q: Will you deliver the right goods as ordered? How can I trust you?

A: Yes, we will. The core of our company culture is honesty and credit. MACTEC is ALIBAB’s Gold supplier with BV assessment. If you check with ALIBABA, you will see that we have never got any complaint from our customers.