High Quality Zinc Roofing Color Steel IBR Sheet Roll Forming Machine

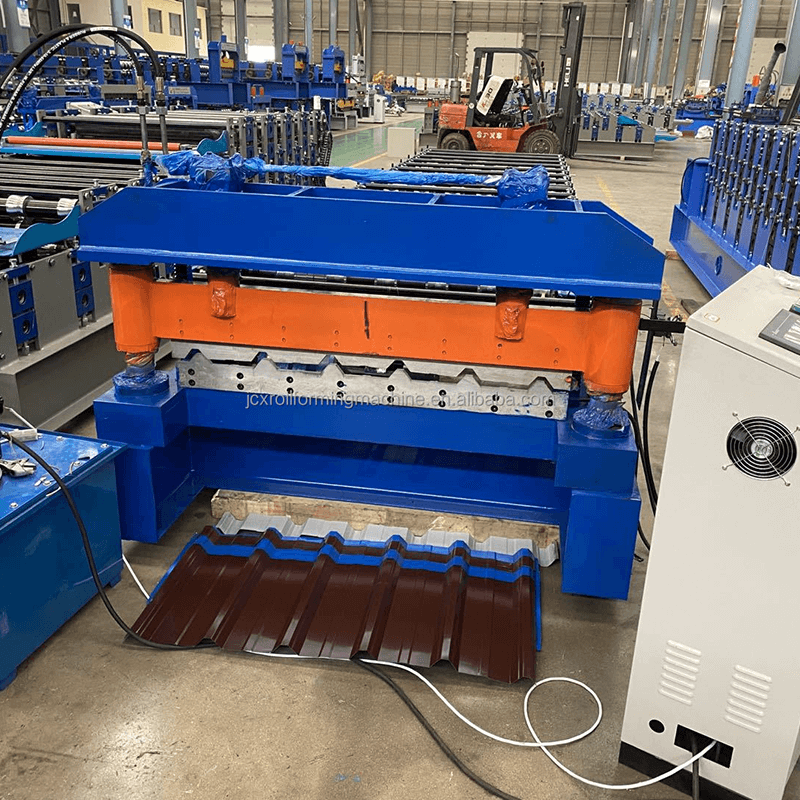

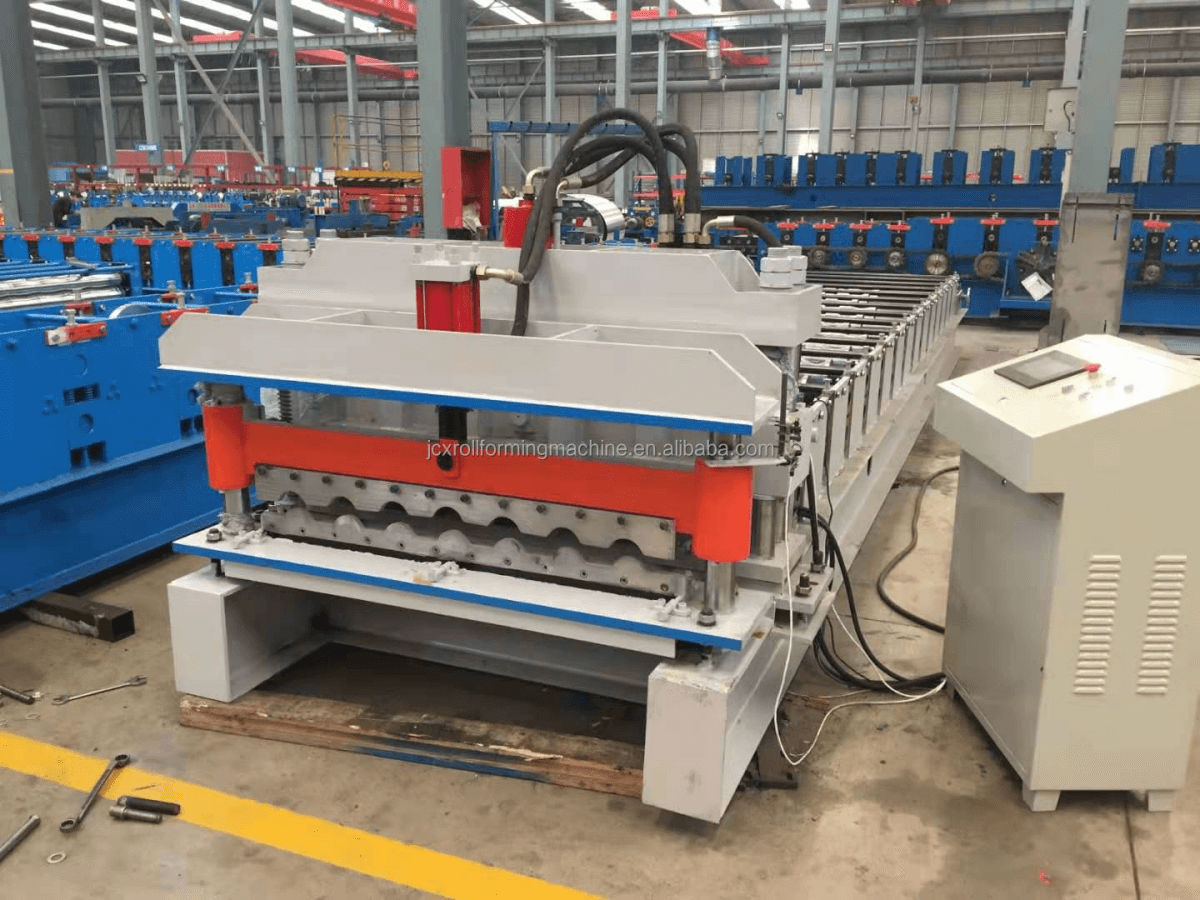

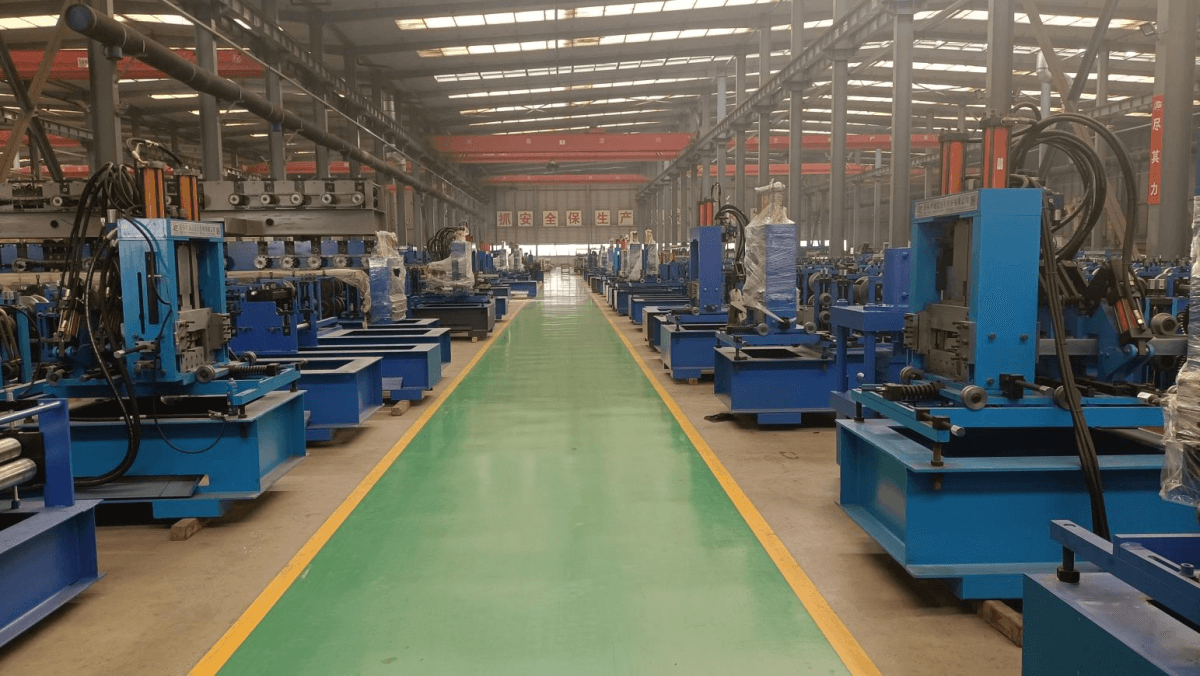

Machine Pictures

One of the main features of this machine is its powerful decoiler, which can easily handle up to 5 tons of material. An optional hydraulic decoiler provides added convenience. In addition, a manual uncoiler is provided free of charge, allowing you to choose the most suitable type of uncoiler according to your needs.

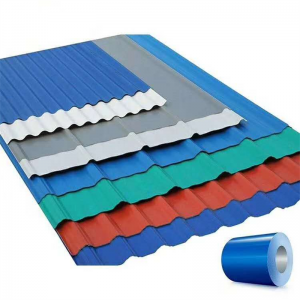

With a forming speed of 12-18 meters per minute, the machine is capable of producing high-quality roof panels at an impressive rate. Zinc roofing color steel IBR sheet roll forming machine is compatible with G235 grade steel or galvanized coils, providing more flexibility for your production process.

The machine's 13 forming steps ensure that each roof panel is properly and consistently manufactured to meet your high standards. The shaft has a diameter of 75 mm and is very strong and durable. Additionally, the shaft is solid, providing a level of reliability unmatched in the industry.

One of the most notable features of this machine is its versatility. Zinc Roofing Colored Steel IBR Sheet Roll Forming Machine is able to handle various thicknesses ranging from 0.3mm to 0.7mm. This makes it the perfect machine for producing a wide variety of roof styles and designs.

Specification

| No | Item | Parameter |

| 1 | Decoiler | 5tons electric decoiler (Hydraulic decoiler optional), manual one free |

| 2 | Forming speed | 12-18m/min |

| 3 | Material | G235grade steel or galvanized coil |

| 4 | Thickness | 0.3-0.7mm |

| 5 | Forming steps | 14 +13forming steps |

| 6 | Shaft | Diameter 75mm, all solid |

| 7 | Rollers | High grade 45# steel with heat treatment and hard chrome coating 0.04-0.05 |

| 8 | Main frame system | H350 steel. By blasting |

| 9 | Motor brand | shanghai lichao motor |

| 10 | Main forming power | 5.5kw. |

| 11 | Pump Station Power | 4Kw, or electric cutting for 3kw |

| 12 | Cutting Type | hydraulic cutting or electric cutting |

| 13 | Cutting Blade | Cr12Mov with hard treatment, HRC52-68 |

| 14 | Control System | Delta PLC, Touch screen, Frequency converter |

| 15 | Measuring accuracy | Precision +/-1.5mm,with frequency converter |

| 16 | Transmission | By single chain 1’ |

| 17 | Machine Dimensions | About 7.5*1.5*1.7m |

| 18 | Machine weight | About 5500 kgs |

| 19 | Voltage | 380V,50hz, 3phase, as per request |

MACHINE COMPONENT

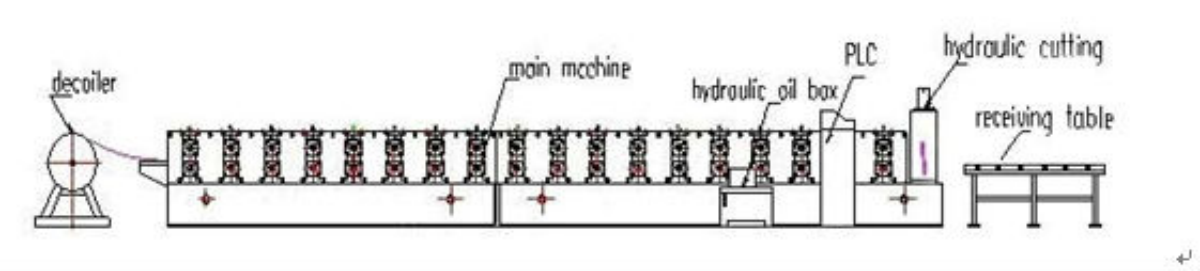

Decoiler

1. Capacity: it bears 5tons .

2. Material coil inner diameter: 450mm-550mm

3. Max width: 1250mm

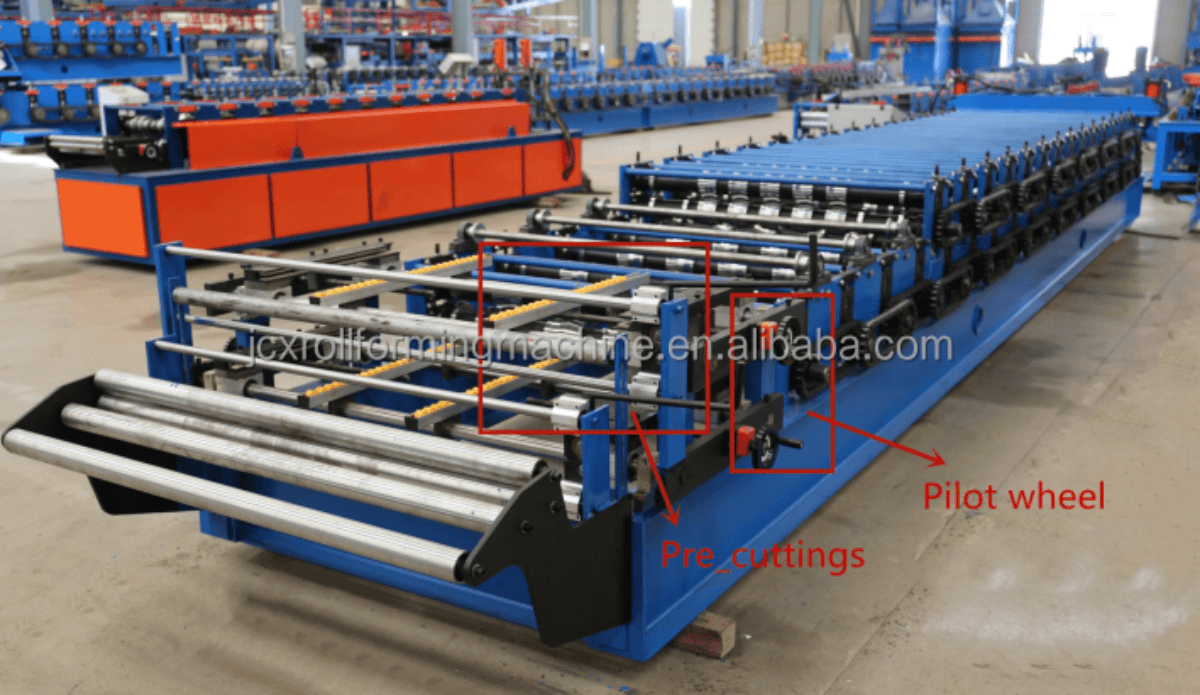

Guiding Device

1. Advanced guiding device, ensure the steel roll in correct direction.

2. Two layers all equip with pre cutting, save steel roll, no waste

Main Forming Machine

Refer to machine parameters

Hydraulic Cutting

Hydraulic cutting system--Guide pillar type or Electric cutting. Speed more faster

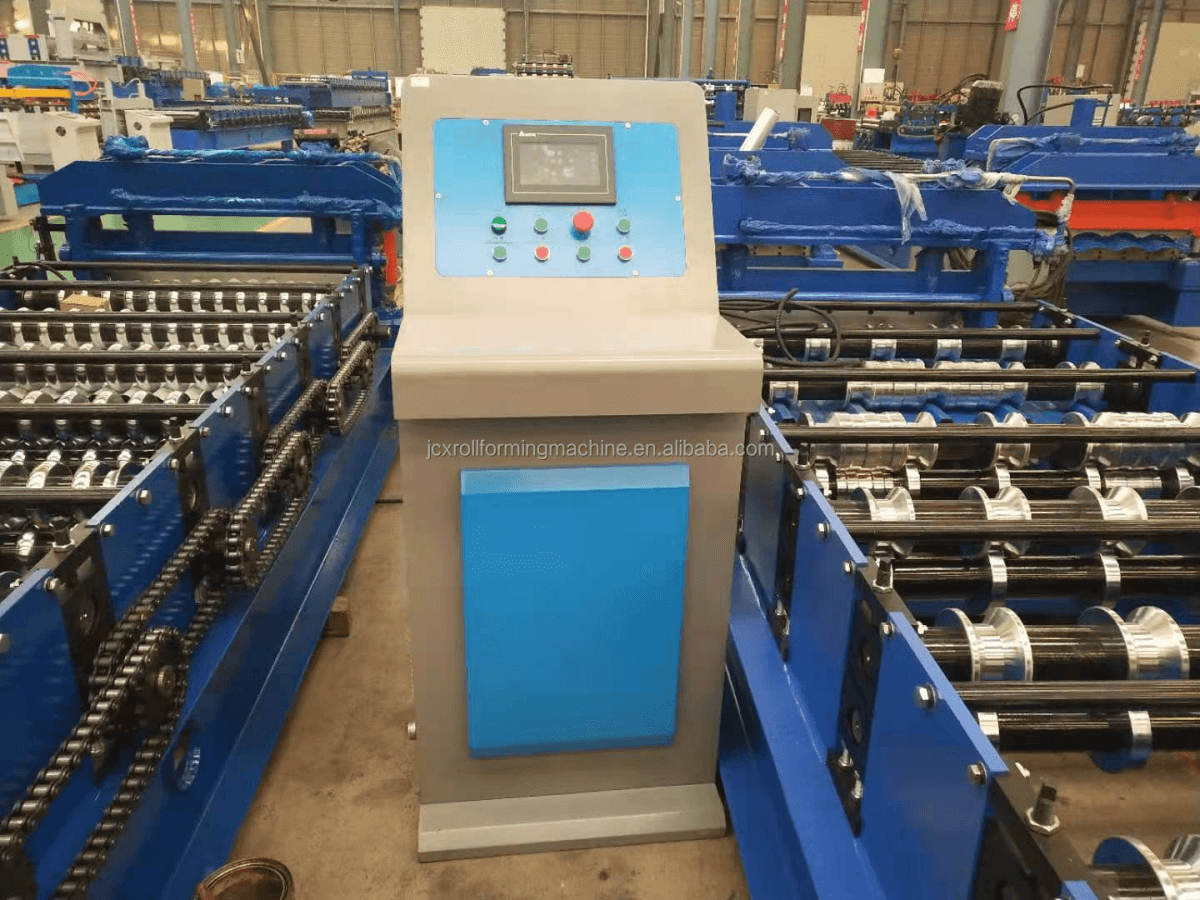

Control system

1). Screen:Delta

2). PLC: Delta

3). Automatic length measurement

4). Automatic quantity measurement

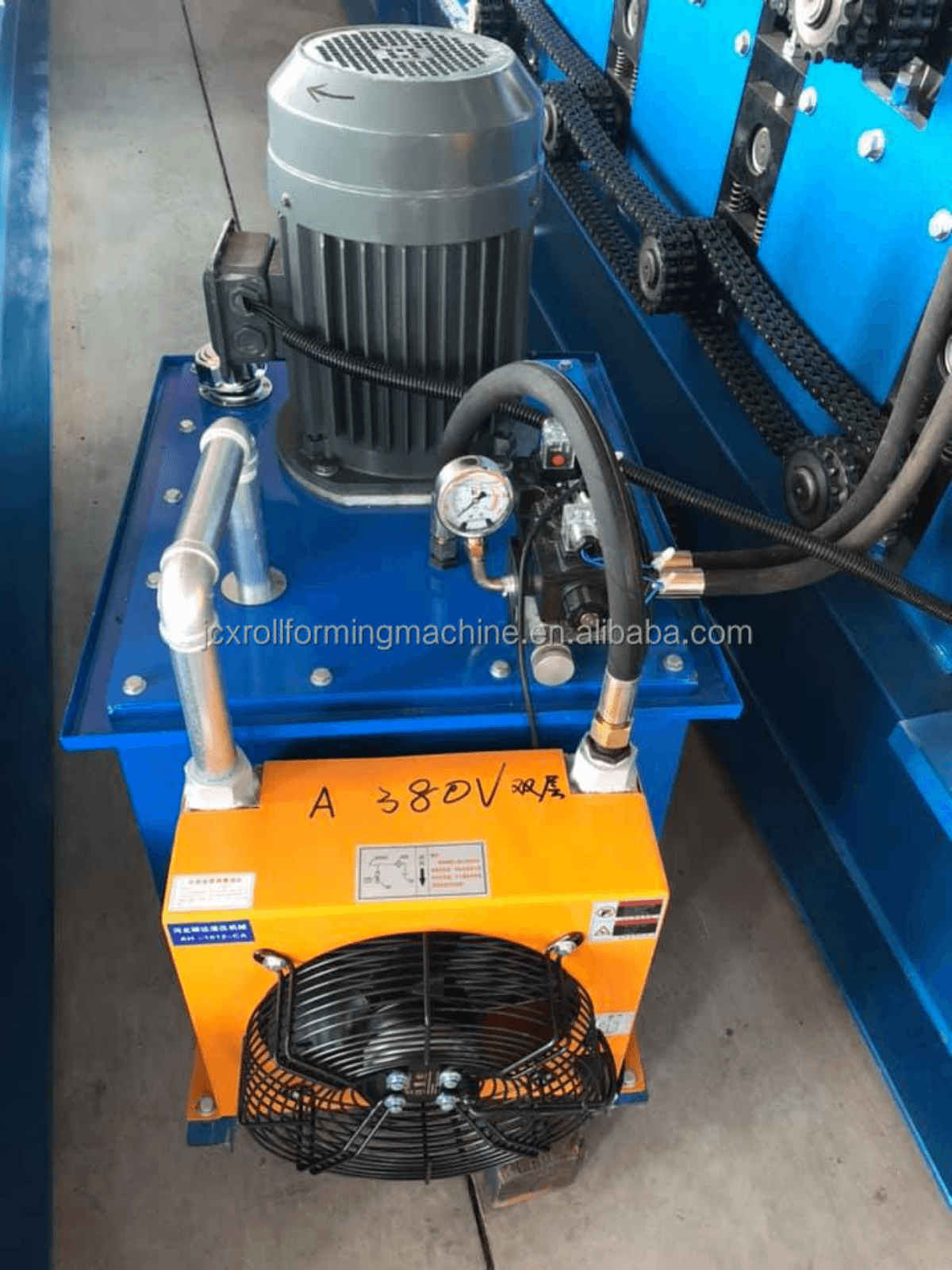

Hydraulic Station

1). Adopt advanced hydraulic system , with cooling fan.

2). Motor:4kw

3). Hydraulic oil: 46#

Packing & Delivery

1. One machine can be loaded in one 40GP container.

2. All machines will be tested before delivery

3. We will send manual book and operating video with the machines to you.

4. All spare parts will be packed in one tool box.

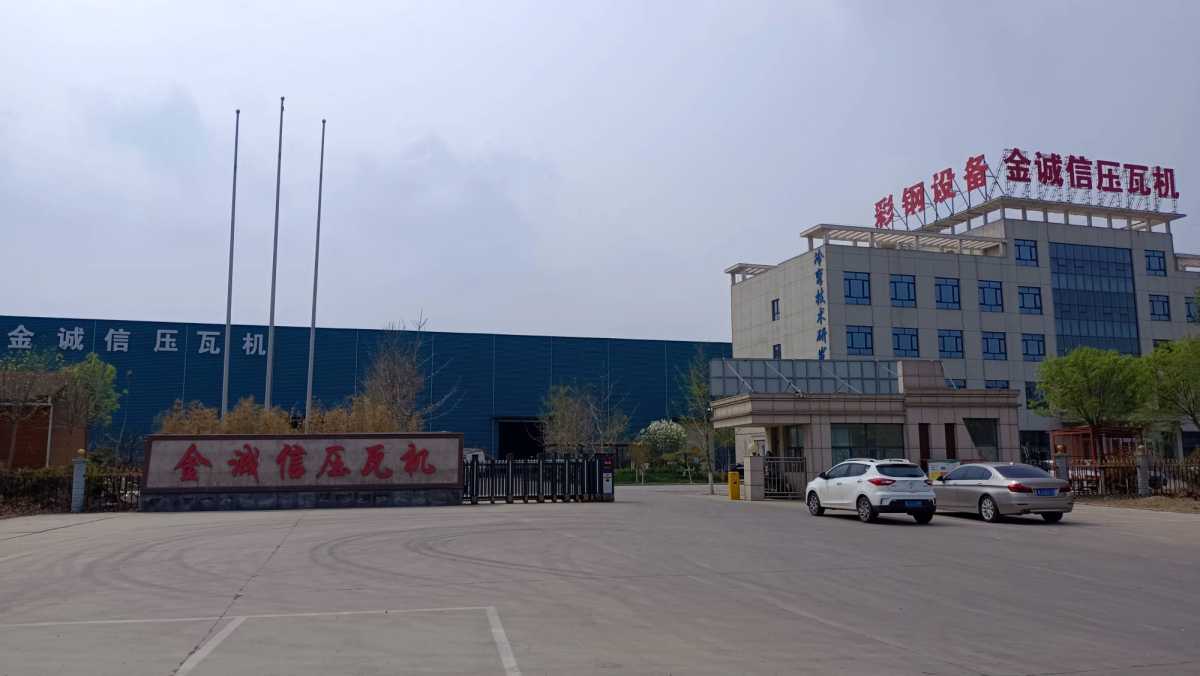

Company Profile

Botou Golden Integrity Roll Forming Machine Factory is located in "the town of casting molds", enjoying convenient and highly effective transportation for being close to Tianjin Port, No.104 National Way, No.106 National Way and Jingjiu Railway. On the basis of traditional roll forming machines, we also develop new computer fully automatic roll forming machines, roof and wall panel forming machines, glazed tile forming machines, floor bearing plate forming machines, high-speed barrier devices, double color steel tile molding machines, C and Z steel machines, arch appliances, sandwich composite plate machines, shearing machines, bending machines, and heat insulation sandwich composite machines. Our products have reached the advanced level in the same industry. As beautiful appearance, reasonable structure, and tile-based standards of our products, they are popular among new and old customers. Products are sold to domestic enterprises.

FAQ

1. Does your company can customized my needed profile?

Yes sir/Madam. Our machines are all customized according to customers' requests. Just provided me your needed profile drawing and we can give you our professional machine design solution.

2. If i don't have profile drawing, but i want to buy one machine, can you help me?

Yes sir/ Madam. If you don't have profile drawings, the solutions have:

2.1 : Provide me with your profiles' pictures ;

2.2 : Tell me your country and i will check if we sell similar / related profile machines to your there. I will recommend you

related profile drawings.

2.3 : Tell me any information you have and it will be helpful for me to clear your needed profiles. and then quote you.

3. What your company advantages?

Yes sir/Madam. Our advantages have :

3.1: We are a 16 years big factory. We have abundant machine designing and making experience. We can give you the best

machine solution.

3.2: We have completed production system. And more than 20 sets of CNC machines which can support lots of machine

orders' making and guarantee the delivery.

3.3 : We have 20 years foreign trade exported experience. Our sellers abundant experience can guarantee you will have a

pleasant purchase and use of the machine and after-sales experience. And cooperated with us , you can get more details about the machine, including those problems that you can't think of but we can think of, we can tell you to ensure that you can buy the most suitable machine for you.

3.4 : We are a golden integrity roll forming machine company. About the after-sale services, no worries, we will responsible for you.

4. Will i receive a good machine ? Same with my wanted ?

Yes sir/Madam. We will do the machine according to your profile drawing . About the profile drawing, we will confirm with you again before producing your machine. Then, after the machine finished, we will test the machine and guarantee the machine you received is a good machine. Because after you satisfied with the machine, and then you pay balance.

5. What is the machine minimum quantity?

One machine is okay.

6. What is your payment terms?

6.1 : We accept 30% T/T as deposit and 70% T/T as balance before shipping.

6.2 : We accept 100% L/C at sight

6.3: We accept Western Union payments.

6.4 : Other payment terms you want to pay, please let me know and i will check and reply you.

Service

Strong Team

We promise that after you place an order, we will design the machine for you as soon as possible according to the factory's arrangement, and arrange the manufacturing and production as soon as the confirmation is completed. Generally, the delivery will be done within 15 natural days after the full payment is received. The specific delivery time can be agreed upon by yourself.

Cost-performance Advantage

Our company has more than 10 years of professional experience in cold bending machinery and cold bending equipment, and nearly 10 years of experience in international cold bending forming machine processing. To be the world's first choice for high-end quality - tile press machinery and equipment manufacturers. This equipment has an original and more advanced and reasonable structure design, which is very convenient and fast to operate, maintain and repair. We especially hope that our products can be favored by your company, and we are willing to serve your company with the best price, excellent quality and after-sales guarantee.